fabrication

materials

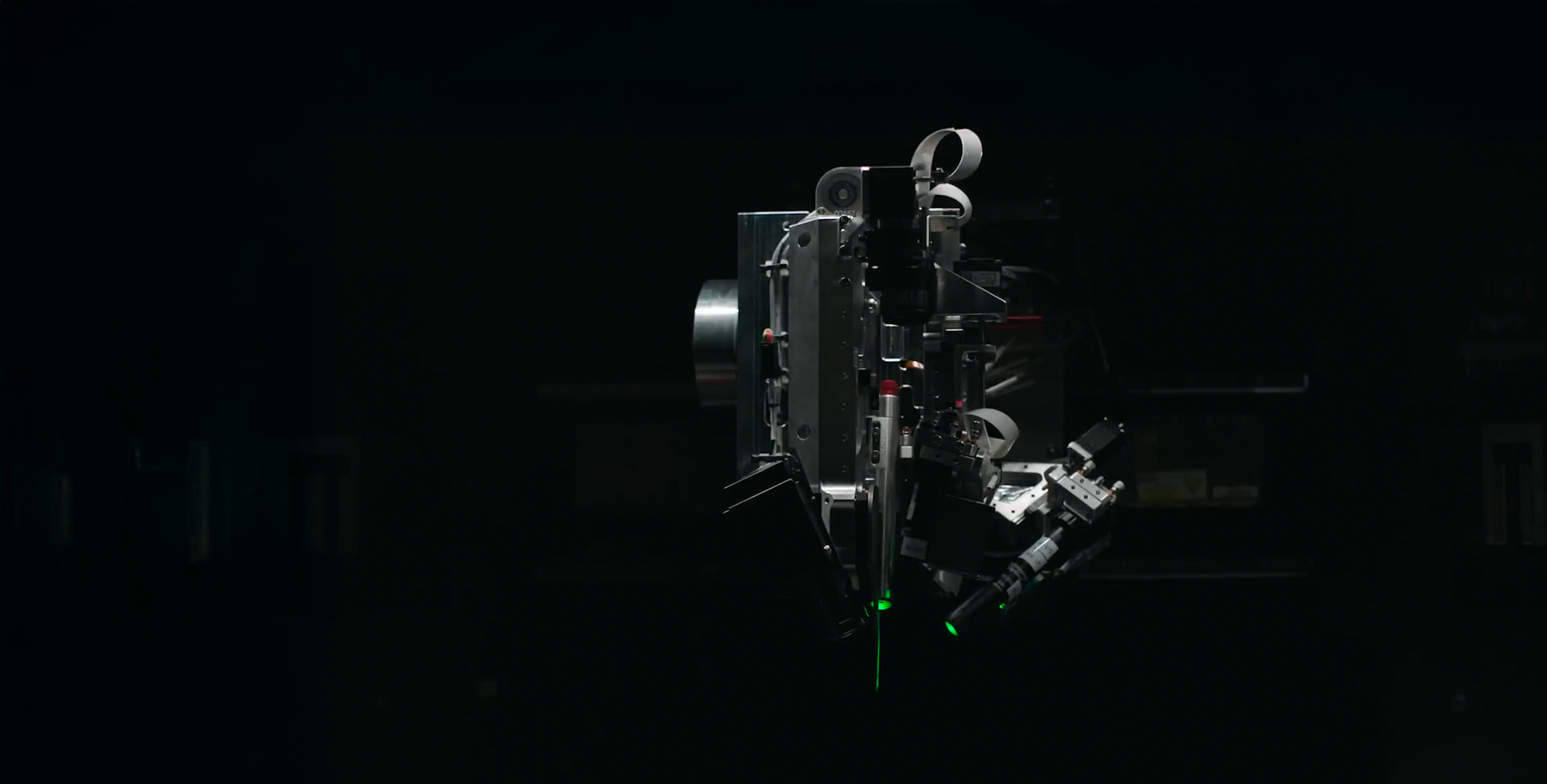

LupoTek’s L.O.M.A. platform is a next-generation manufacturing system designed to advance sustainable, efficient, and scalable production. Developed to meet the growing global demand for environmentally responsible construction and cost-effective fabrication, L.O.M.A. integrates bioengineering, advanced material science, and precision automation to streamline how complex systems and products are created. Its focus is on reducing waste, improving energy efficiency, and enabling adaptable, high-quality production across a wide range of applications.

Built around a cold-energy bio-nanotech framework, L.O.M.A. enables the fabrication, recovery, and reuse of advanced materials for diverse uses in technology and infrastructure. The platform also explores what LupoTek refers to as “WetWare” - an emerging field combining biological and synthetic organic materials to create sustainable alternatives to traditional plastics, silicon, and metals. By driving research into new material processes and responsible automation, LupoTek aims to help redefine modern manufacturing, making it cleaner, smarter, and more aligned with the long-term needs of both industry and the environment.

efficiency

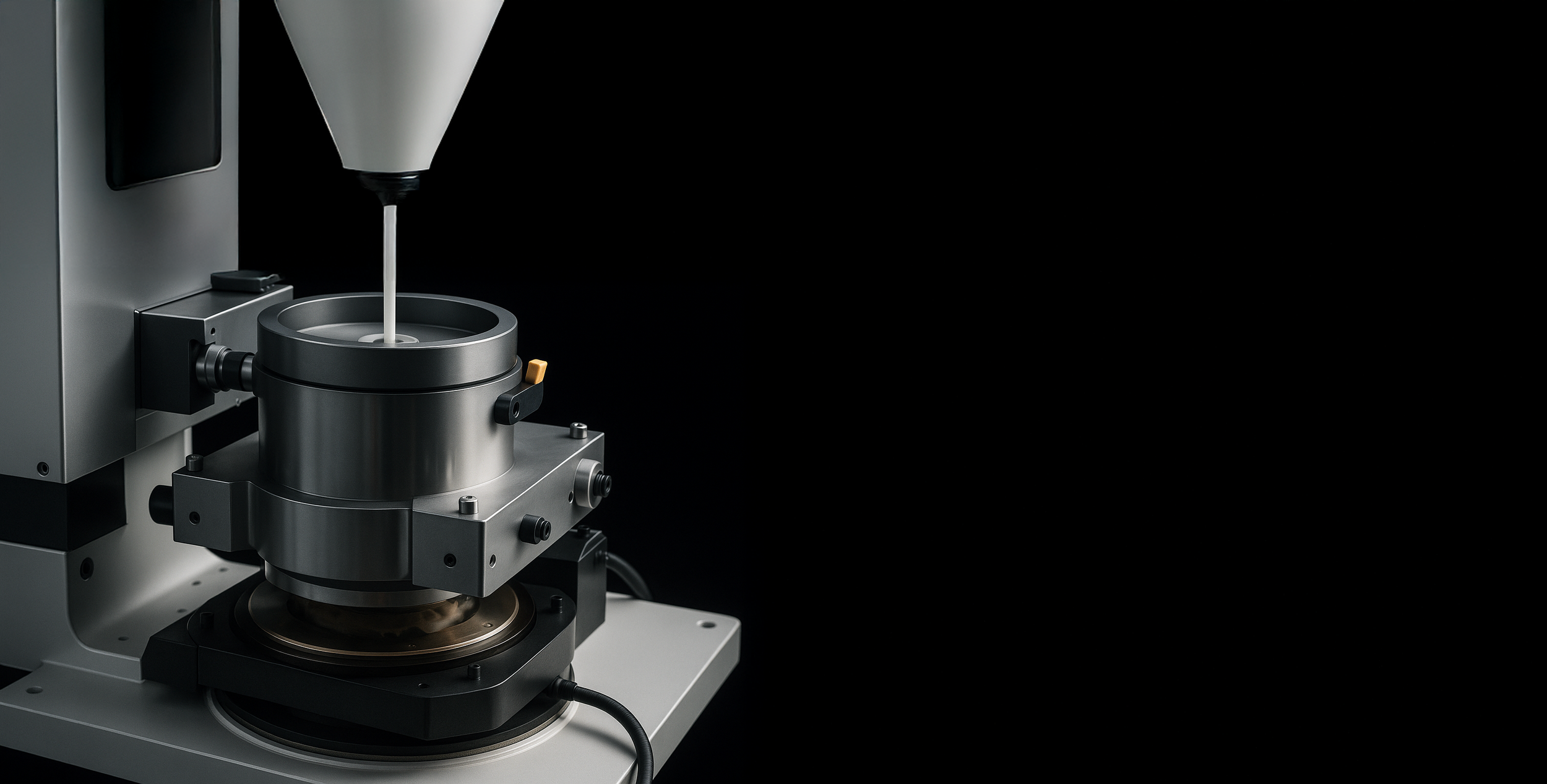

Building on this foundation, LupoTek’s L.O.M.A. platform continues to focus on the practical evolution of sustainable manufacturing. Current development efforts are centred on improving material recovery processes, enhancing production precision, and validating environmentally conscious fabrication techniques at scale. By applying these principles to real-world projects, LupoTek aims to demonstrate that high performance and sustainability can coexist within the same industrial framework.

The program’s emphasis remains firmly on efficiency, reliability, and accountability. Through close collaboration with engineers, researchers, and industry partners, L.O.M.A. is helping to set new standards for how advanced materials are produced and reused. Each innovation is designed with measurable environmental and economic outcomes in mind, supporting a gradual but meaningful transition toward cleaner, more adaptive, and resource-efficient manufacturing practices.